|

Almost like the search for the Holy Grail, the quest for greater visibility has similarly been driving supply chains across the globe for the past decade.

One could argue that the Supply Chain Visibility era started in the late 1990s, when Art Mesher, then an analyst at Gartner and now CEO of Descartes Systems, wrote a series of research notes on "The Three V's of Supply Chain," which were velocity, variability, --- and visibility.

From that point on, visibility has been at the forefront of supply chain issues, and improving the level of visibility has moved in the last 7-10 years to the top of the corporate supply chain priority list for the majority of companies.

Gilmore Says: |

Not only is this simply a concise but powerful vision of where we are headed, but again shows how visibility has moved well beyond just �where�s my stuff?� Not only is this simply a concise but powerful vision of where we are headed, but again shows how visibility has moved well beyond just �where�s my stuff?�

Click Here to See

Reader Feedback |

Ah but what is it, really? Can a company ever really achieve a satisfactory level of visibility? What are the keys to success?

We tackle these questions and more in our latest version of the Supply Chain Digest Letter, this month focused on Supply Chain Visibility. I proudly say it is one of our best ever. Mail copies of the full 16-page Letter are on their way to select readers. An e-version of the Letter can be accessed here: SCDigest Letter on Supply Chain Visibility 2012. Our full resources page is here: Supply Chain Visibility Information and Resources page.

I cannot possibly well summarize the full contents of the Letter in this space, but can relay some key thoughts and points.

First, as I have said for the last decade or so, I really do believe that supply chain visibility is very much like the proverbial onion: it has many layers that must be peeled back over time to reveal more and more data and insight to a company's managers and executives. When progress is made, it at first appears that this new level of visibility has solved many existing problems. But over time, that level of visibility seems not nearly sufficient, and the company must look to peel away another layer of the onion to address another set of challenges or opportunities.

Second, there are no longer any real technical barriers to achieving near perfect visibility, and it is coming soon to a supply chain near you. Auto ID/RFID, GPS, video, mobile, wireless, sensors, the Cloud, etc. – these are largely very mature technologies. The costs for most keep going down. To really get where we can go with this, we’ll need to see RFID adoption pick up some more, as in some applications bar coding provides challenges, but really RFID technology is moving along nicely, regardless of the initial Walmart RFID mandate debacle.

So the technology is there – what is missing? Well, along with the onion analogy, it just takes companies time to mature and evolve. That said, some are clearly evolving lot faster than others. We recently did an interview with an executive at Levi’s, which has developed a very aggressive visibility platform (the video interview is available on the Visibility Resources Page). The real point is that it just seems that Levi’s and others have really just mustered the will (that really is the best word to describe it) to achieve a high level of visibility, while most still nibble around the edges.

Visibility is a complex thing, touching nearly every aspect of the supply chain. The initial thinking was primarily a logistics-oriented one – “where’s my stuff?” That is still a very important question, especially with both Lean and global supply chains trying to exist simultaneously), but visibility thinking and action has gone way beyond that today, embracing demand and supply visibility, risk visibility, and more.

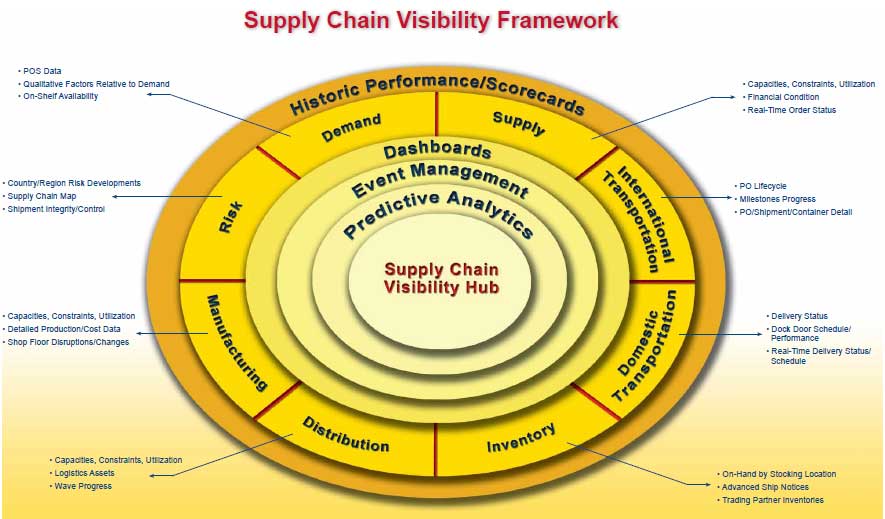

For this Letter, we developed a new Supply Chain Visibility framework that encompasses eight “vectors” of visibility information and insight. It then incorporates concepts related to performance management and analytics that are also components of visibility. You will find a small version of it below. A link to a larger image is right below this smaller one.

Source: Supply Chain Digest

You will note we have at the center something called a “Visibility Hub.” We may never get there, but the ultimate end game would be the creation of a central portal that would contain integrated visibility information across all the eight sectors.

As we note in the Letter, such a hub might be seen as analogous to the "grid" capabilities supposedly developed by the FBI, CIA, and other government entities. That grid brings in information from a wide variety of sources (credit card usage, cell phone and other calls, bank records, and who knows what else) that not only can be made visible in the effort to investigate, thwart or find the bad guys, but also can link that visibility data across sources. Or at least, that is what the TV show NCIS and others would have you believe. I believe it is true.

Here today for supply chain? Not quite yet, though so-called “Control Towers” in the logistics arena provide a type of model for it. Are vendors working on somewhat analogous concepts for even wider supply chain data beyond logistics? Absolutely.

What I think many don’t appreciate are the changes that this level of “turbo visibility” is going to bring eventually. It will drive rethinking about our existing supply chain organizations, especially as operational planning and execution start to blur into one thing. We actually didn’t use this in the Letter, but one of my all-time favorite quotes relative to visibility comes from Nick LaHowchic and the late Dr. Don Bowersox from their excellent book “Start Pulling Your Chain” from a few years ago.

They wrote: “If informationwas shared fluidly between participating firms in a channel, then a great deal of “anticipation” would be replaced with facts. In a collaborative environment, it would not be necessary to forecast what others are planning to do or what they are planning to buy. You would see it.”

Not only is this simply a concise but powerful vision of where we are headed, but again shows how visibility has moved well beyond just “where’s my stuff?”

I will close it off here with just one very interesting example of a “visibility fail.” When the financial crisis and the recession hit in 2008 into 2009, the high tech and consumer electronics industry almost completely froze, as a lack of visibility caused something like a reverse Bullwhip Effect. In Q4 of 2008, consumer purchases were down 8%, but final goods shipments were down 10%, and component orders were down 20%. This was in large part because the tier ones and two didn't know have good visibility to what was happening at the consumer level, and thus feared the worst.

Best Buy later said it could have sold a lot more stuff if suppliers had only sent it.

Oh, and did I add that this turbo visibility will result in Perfect Logistic? You will find that in the Letter too.

What are our views on supply chain visibility? How will it impact our supply chains? Let us know your thoughts at the Feedback button below.

|